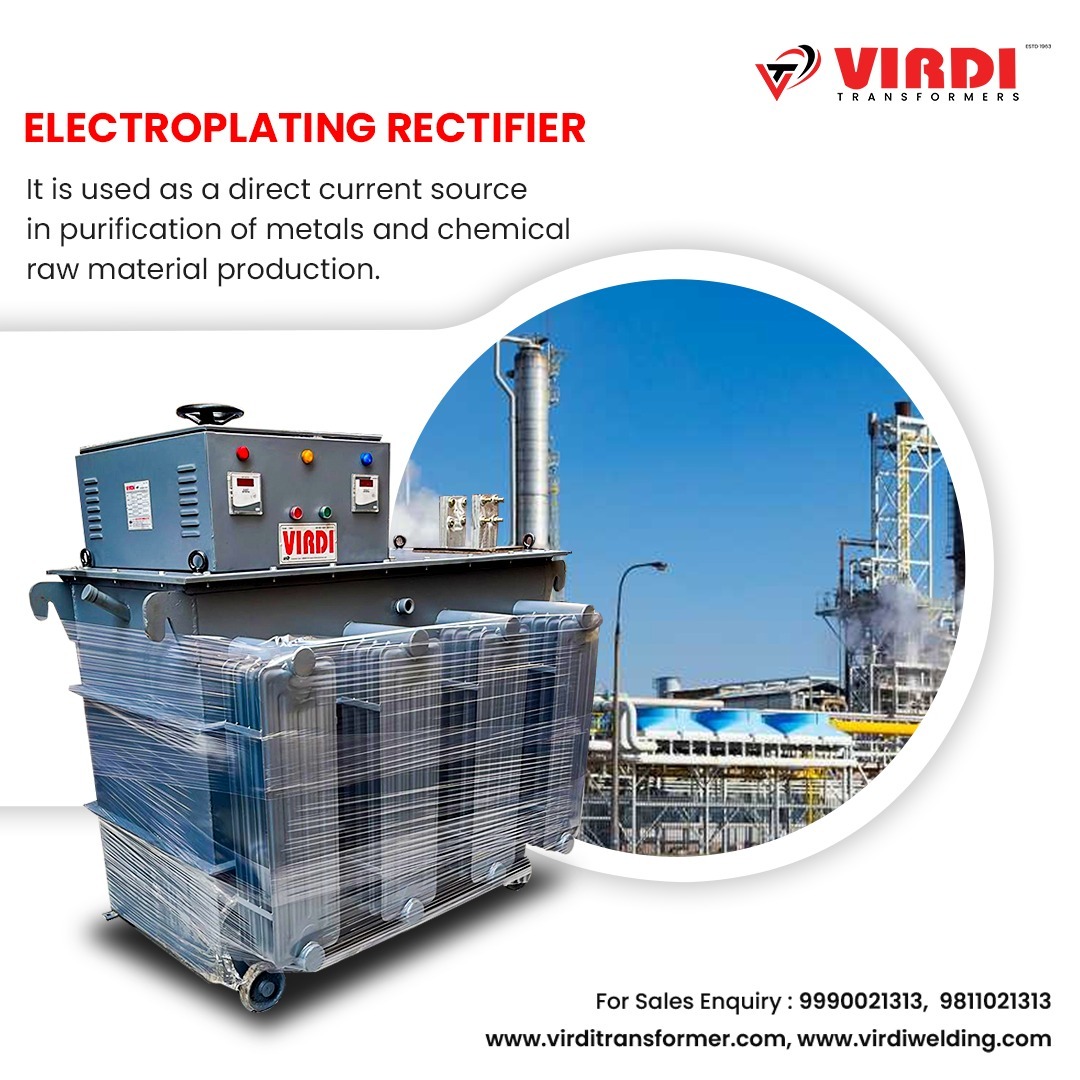

Electroplating Rectifier

Electroplating Rectifier Specification

- Product Type

- Silicon Controlled Rectifier

- Application

- Copper Electrolyte Strip

- Input Voltage

- 0-220 Single Phase /380/400 volts Three Phase Volt (V)

- Output Frequency

- 50 Hz Hertz (HZ)

- Warranty

- 1 Years

Electroplating Rectifier Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Others

- Supply Ability

- 200 Units Per Month

- Delivery Time

- 3 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Customized.

- Main Domestic Market

- All India

- Certifications

- ISO, NSIC,MSME

About Electroplating Rectifier

VIRDI Make Electroplating Rectifier

* Single And Three Phase

* Single Phase Amps :- 50 /100 /150 200/ 300 Amps

* Three Phase Amps :- 100/ 300/ 500/ 750/ 1000/ 1500/ 2000/ 2500/ 3000/ 4000/ 5000/ 6000/ 7000/ 8000/ 1000 Amps

* Sec Volt :- 0 to 12/ 16/ 20/ 24 Volts D.C. Variables by means of step less on load carbon Brushes Contact With the help of rises/ lowers by manually.

* 0-220 Single Phase / 380/440 Three Phase

*Frequency 50 Hz A.C. Supply

* Efficiency Better Than 98%

*Oil And Air Cooled

* Laminations Strip :- CRGO

*Losses at No Load :- 0.25% of the total capacity

* Losses at Full Load :- 0.70% at full load

Product details

|

Country of Origin |

Made in India |

|

Warranty |

1 Year |

|

Operating Temp. |

45 Degree C |

|

Frequency |

50 Hz |

|

I Deal In |

New Only |

|

Material |

Mild Steel |

|

Color |

A.D Gray |

|

Phase |

Three Phase |

|

Voltage |

12 Volts |

|

Current |

750 Amp |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electroplating Rectifiers Category

2000 Amps Three Phase Oil Cooled Electroplating Rectifier

Price 330000 INR / Unit

Minimum Order Quantity : 1 Unit

Input Voltage : 380415 Volt (V)

Application : Copper Electrolyte Strip

Warranty : 1 Year

Color : AD Gray

5000 Amps Three Phase Electroplating Rectifier

Price 685000 INR / Unit

Minimum Order Quantity : 1 Unit

Input Voltage : 380415 Volt (V)

Application : Copper Electrolyte Strip

Warranty : 1 Year

Color : AD Gray

3000 Amps Three Phase Oil Cooled Electroplating Rectifier

Price 485000 INR / Unit

Minimum Order Quantity : 1 Unit

Input Voltage : 380415 Volt (V)

Application : Copper Electrolyte Strip

Warranty : 1 Year

Color : AD Gray

1000 amps Three Phase Electroplating Rectifier

Price 210000 INR / Unit

Minimum Order Quantity : 1 Unit

Input Voltage : 380415 Volt (V)

Application : Copper Electrolyte Strip

Warranty : 1 Year

Color : AD Gray